1. Raw material supply management

Selection and procurement: Ensure that the source of raw materials is stable and high-quality. For the production of bio-organic fertilizers, such as the use of livestock and poultry manure, it is necessary to cooperate with stable farms to ensure the continuity of supply. At the same time, establish raw material quality standards, strictly test the organic matter content, humidity and other indicators of raw materials, and avoid production interruptions or poor product quality due to unqualified raw materials.

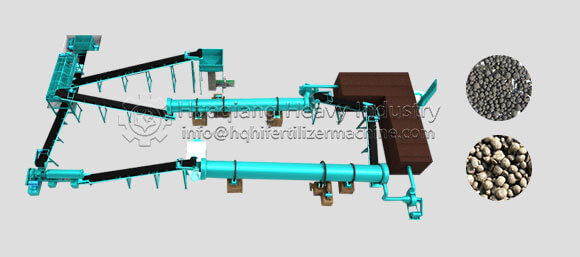

Storage and transportation: Build suitable raw material storage facilities, such as well-ventilated warehouses, to prevent raw materials from deteriorating. Optimize the raw material transportation system and use automated conveyor belts and hoppers to ensure that raw materials can be delivered to the production link in a timely and accurate manner, reducing production stagnation caused by untimely raw material supply.

2. Optimization of the fermentation process

Control of microbial flora: Screen efficient microbial strains, which should have the characteristics of rapid decomposition of organic matter and adaptability to a variety of raw materials. Reasonably adjust the inoculation amount and inoculation time of microorganisms, and accurately control them according to the type and quantity of raw materials to start the fermentation process quickly.

Control of the fermentation environment: Use intelligent sensors to monitor the fermentation temperature, humidity and oxygen content. Keep the temperature in a suitable range, ensure the stability of the fermentation environment through ventilation equipment and humidity control devices, and shorten the fermentation cycle.

3. Upgrade of production equipment

Crushing and mixing equipment: Use efficient crushing equipment to crush the raw materials finer and more evenly, and increase the contact area between microorganisms and raw materials. Upgrade mixing equipment to ensure that different raw materials can be fully mixed to provide good conditions for fermentation.

Granulation and packing equipment: Use high-speed and high-precision granulation equipment (such as Rotary Drum Granulator) to improve granulation efficiency and particle quality. Automated packing equipment can complete packing tasks quickly and accurately, reducing manual errors and time waste.

4. Strict quality monitoring system

Process monitoring: Set up multiple detection points on the bio-organic fertilizer production line to monitor product quality indicators in real time, such as nutrient content, pH, etc.

Feedback adjustment: Adjust production parameters in time according to the test results to ensure stable product quality and avoid reduced production efficiency due to quality problems.

In short, improving the production efficiency of the bio-organic fertilizer production line is a systematic project that requires multiple aspects to achieve efficient and high-quality production.