To establish an efficient fertilizer production line, it is not only necessary to consider the selection of equipment, but also to comprehensively evaluate the source of raw materials, production process, site layout and market demand. Reasonable planning can ensure the stable operation of the production line and improve the return on investment.

1. Determine the source and formula of raw materials

Before building a NPK fertilizer production line or organic fertilizer production line, it is necessary to first clarify the type and source of raw materials. Common organic fertilizer raw materials include livestock and poultry manure, crop straw, food waste, etc. Different raw materials have different water, carbon and nitrogen ratio, and decomposition cycle, which directly affect the subsequent process and equipment configuration.

2. Choose the right production process

The production process of organic fertilizer includes fermentation, crushing, granulation, screening, packaging and other links. Among them, the choice of fertilizer granulator is particularly critical. Common granulation methods are disk granulation, extrusion granulation and roller granulation, and different processes are suitable for different types of raw materials and production needs.

3. Site planning and environmental requirements

Reasonable plant layout can improve production efficiency and reduce material handling costs. At the same time, fertilizer production involves organic fermentation, which may produce odor, so environmental protection measures need to be considered, such as deodorization equipment and sewage treatment systems, to ensure compliance with local environmental protection policies.

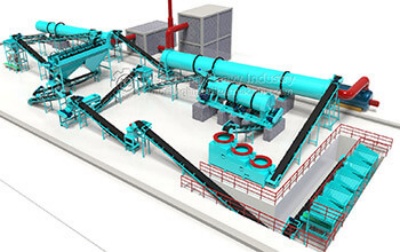

4. Equipment selection and automation degree

According to the production capacity requirements, choose the right fertilizer production line equipment, such as tipping machine, crusher, granulator, dryer, etc. In addition, the higher the degree of automation, the higher the production efficiency, the lower the labor cost, but the investment cost will also increase, so it needs to be reasonably allocated in combination with the budget.

5. Market demand and sales channels

Before establishing the NPK fertilizer production line, it is also necessary to investigate the market demand, determine the product specifications (powder, granular, etc.) and sales model (wholesale, retail, export, etc.), to ensure that the fertilizer produced can quickly enter the market, forming a virtuous cycle.

Conclusion

Before the establishment of fertilizer production lines, enterprises need to comprehensively consider raw materials, processes, environmental protection, equipment and market factors to ensure that the production line is efficient, environmental protection and economic, laying the foundation for subsequent stable operation.